Views: 0 Author: Site Editor Publish Time: 2026-01-21 Origin: Site

In the complex ecosystems of automotive, industrial, and consumer electronics, system downtime is rarely caused by the catastrophic failure of a major component. It is not usually the engine control unit or the power supply that fails first. Instead, the leading cause of intermittent faults and total system failure is often the connection point itself. While wires conduct electricity, the female connector—the socket or receptacle—acts as the guardian of that continuity.

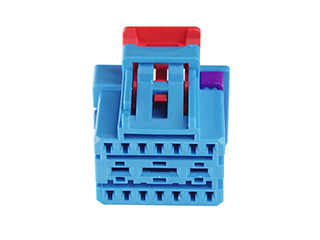

Far from being a simple passive port, the female connector bears the heavy responsibility of maintaining mechanical retention, ensuring environmental sealing, and protecting users from dangerous voltages. It provides the necessary pressure to keep circuits closed even under intense vibration or thermal expansion. When you select a female connector, you are defining the reliability lifespan of the entire assembly.

This guide explores the engineering logic behind why specific connectors are chosen for critical roles. We will dismantle common terminology traps that lead to procurement errors, such as the confusion between housings and terminals. Finally, we will outline the evaluation criteria required to select components that survive in high-stress environments.

Safety First: Why female connectors are almost universally assigned to the live (hot) side of a circuit to prevent shocks and shorting.

Terminology Traps: How to distinguish between plugs, jacks, and receptacles to avoid costly procurement errors.

Reliability Metrics: The role of contact spring force, mating cycles, and TPA (Terminal Position Assurance) in preventing signal loss.

Application Logic: Matching contact materials and housing types to specific stressors like automotive vibration or data signal interference.

In almost every industry standard, from residential wiring to automotive harnesses, the female connector is assigned to the hot or live side of the circuit. This is not a random convention; it is a calculated engineering decision driven by safety and reliability.

The primary reason you terminate the power source—whether it is a battery, a wall main, or a power supply unit—to the female connector is isolation. Female connectors feature recessed contacts housed deep within a plastic or rubber insulator. This design prevents accidental human contact with live circuits.

Consider a loose cable connected to a car battery. If that cable ended in an exposed male pin, it could easily brush against the vehicle’s metal chassis (ground), causing a catastrophic short circuit, sparks, or fire. By using a female socket, the conductive elements remain shielded within the housing, making it physically difficult for the live contact to short against a ground plane or shock a technician.

Beyond electrical safety, the female housing serves as a physical shield. Male pins are inherently more fragile; they can be bent, crushed, or misaligned if dropped or handled roughly. The female connector housing is typically designed to be slightly larger and more robust. During the mating process, the female housing acts as a guide, shrouding the male pins and aligning them before the metal contacts actually touch. This alignment feature prevents stubbing—where a male pin hits the face of the connector rather than entering the socket—which can destroy a harness.

In high-voltage power distribution, disconnecting a circuit under load can create an electrical arc. This arc is a flash of electricity that jumps across the gap as the contacts separate. Female sockets are generally designed with deep cavities. These cavities help contain the arc flash within the housing, protecting the user and preventing the arc from jumping to adjacent circuits. This containment is a critical specification for any high-power connector used in electric vehicles or industrial machinery.

A connector might look robust on the outside, but its reliability is determined by the physics occurring inside the housing. When evaluating specifications, you must look past the plastic shell and focus on the mechanics of the terminal contact.

The heart of any female connector is the spring mechanism inside the socket. This mechanism applies normal force—the perpendicular pressure exerted against the male pin. This pressure is what cuts through oxidation layers and maintains conductivity.

A critical decision factor here is mating cycles. Every time you insert a pin, the female spring expands. Over time, poor-quality materials suffer from stress relaxation, where the metal loses its memory and fails to spring back. This results in a loose connection that causes intermittent faults, especially when the device heats up. High-quality connectors use copper alloys like phosphor bronze or beryllium copper to maintain high elasticity over hundreds or thousands of cycles.

| Feature | Standard/Economy Connector | High-Reliability/Automotive Connector |

|---|---|---|

| Contact Material | Brass (Low elasticity) | Phosphor Bronze / Beryllium Copper (High elasticity) |

| Normal Force | Decreases rapidly after heat cycling | Stable retention force over lifespan |

| Failure Mode | Intermittent open circuits (loose fit) | Consistent connection until rated cycle limit |

Even the best metal terminal is useless if it backs out of the plastic housing. Secure retention is achieved through a two-stage locking system:

Primary Locks: This is the plastic latch inside the housing cavity that snaps the metal terminal into place. When you assemble the connector, you hear a distinct click. This indicates the primary lock has engaged.

Secondary Locks (TPA): For high-vibration environments, primary locks are insufficient. Engineers specify connectors with Terminal Position Assurance (TPA). These are plastic wedges or combs inserted into the housing after the terminals are seated. The TPA physically blocks the terminals from vibrating backward and backing out of the connector. If a TPA won't seat properly, it alerts the assembler that a terminal is not fully inserted.

Reliability also depends on keeping the elements out. In female housing designs, look for integrated silicone ribs or radial seals. Unlike male housings which often just provide a smooth surface, the female interface usually contains the gasket that compresses against the mating part. This seal is vital for achieving IP67 or IP68 ratings, preventing moisture ingress that leads to galvanic corrosion.

One of the most frustrating aspects of sourcing electrical components is the inconsistent terminology. Confusing a plug with a socket can delay production lines by weeks. The confusion often stems from looking at the plastic housing rather than the electrical contact.

In consumer electronics, the gender is usually obvious: the part with the holes is female. However, in automotive and industrial series (such as Deutsch DT or Delphi Weather Pack), this visual cue is deceptive. You might encounter a plastic housing that fits inside another housing—a trait typically associated with male parts—yet it contains female sockets.

The Golden Rule: Always identify gender by the metal terminal (the conductive part), not the plastic shell.

If the metal contact is a pin or blade? It is Male.

If the metal contact is a hole, cup, or clamp? It is Female.

Manufacturers use different naming conventions, which complicates cross-referencing parts. Understanding these distinctions is vital for accurate ordering.

| Standard Term | Automotive/Industrial Term | Description |

|---|---|---|

| Male | Header / Tab / Pin / Cap | Contains the solid metal pin or blade. |

| Female | Receptacle / Socket / Jack / Plug | Contains the hollow metal cylinder or spring clamp. |

Actionable Advice: Never rely on the product name alone. Always check the datasheet for the Mating Part number and visually verify the terminal type. In some catalogs, a Plug refers to the mobile part of the assembly regardless of gender, while a Header refers to the fixed PCB mount.

Not all connectors are created equal. A female USB port on a laptop faces entirely different stressors than a fuel injector connector on a diesel engine. Selecting the right component requires matching the design features to the specific environmental stress.

In these sectors, the enemies are vibration and thermal cycling. An engine bay can fluctuate from -40°C to +125°C, causing materials to expand and contract. If the female socket loses its grip during expansion, the signal is lost.

Solution: Prioritize connectors that offer high contact wipe. This is a cleaning action that occurs during insertion, where the female spring scrapes the male pin to remove oxides. Additionally, look for robust locking tabs, such as blade or bullet styles for power circuits, and multi-pin headers with TPA for Electronic Control Units (ECUs). The TPA is non-negotiable here; without it, vibration will eventually dislodge the wires.

For data transmission, mechanical retention takes a backseat to Signal Integrity (SI) and Electromagnetic Interference (EMI) protection. A poor connection here doesn't just stop the power; it creates noise and data loss.

Solution: Female ports for HDMI, USB, or RJ45 must have extremely tight manufacturing tolerances to match impedance standards (e.g., 50 or 100 ohms). High-quality female data connectors feature full metal shielding—a grounding shell that surrounds the signal pins. This shield connects to the chassis ground, protecting the sensitive data path from external radio frequency interference.

When transmitting high amperage, resistance is the enemy. Resistance generates heat. If a female terminal has a weak grip or poor plating, the contact resistance rises, potentially melting the plastic housing.

Solution: Investigate contact materials. For logic signals (low voltage/low current), gold plating is preferred because it resists corrosion. However, for high-power distribution, tin or silver plating is often superior because these softer metals deform slightly under pressure, creating a larger contact surface area. Ensure the housing design includes adequate thermal relief or venting if the connector will be carrying continuous high current.

When a system fails, the female connector is often the hardest component to inspect because the contacts are hidden. Technicians must know what to look for to differentiate between a bad sensor and a bad connection.

The most common failure mode is a spread terminal. This happens when a probe used for testing is forced into the socket, or simply through age and vibration. The metal spring widens, and it no longer grips the male pin tight enough.

To diagnose this, technicians perform a pin drag test. They insert a standard male pin into the female socket and feel for resistance. If the pin falls out or slides in with zero friction, the terminal is spread and must be replaced. It is a subtle failure that causes ghost electrical gremlins.

Because female sockets are recessed, they are difficult to clean. If a seal fails and saltwater or road grime enters, the moisture gets trapped inside the cavity. This leads to green copper corrosion that insulates the contact. Unlike male pins which can be easily brushed clean, a corroded female socket often requires replacement because you cannot effectively clean the internal spring surface without damaging it.

When a failure is confirmed, you face a decision: Re-pin or Replace?

Re-pinning: This involves using a specialized removal tool to unlock the plastic tab, sliding the old wire out, and crimping a new terminal on. This is cost-effective but requires high skill and specific tools.

Pigtail Replacement: This involves cutting the harness and splicing in a pre-wired connector assembly. This is often safer for sealing integrity, as the factory-crimped pigtail guarantees the wire seals and TPA are correctly installed.

The female connector is the anchor of system reliability. It handles the power delivery, protects the user from high voltage, and secures the physical connection against the elements. While it may seem like a commodity part, the engineering behind its spring force, material plating, and locking mechanisms defines the quality of the final product.

When selecting components, look beyond the price per unit. Prioritize durability metrics like mating cycles, safety features like arc containment, and retention assurances like TPA. By choosing the right female connector, you are ensuring that your electrical system remains robust, safe, and functional for its entire service life.

A: Yes. While they typically receive power (input), they often output data signals. A common example is a headphone jack on a stereo or laptop. The jack is a female connector, but it outputs the audio signal to the headphones. The gender determination is mechanical, not directional regarding signal flow.

A: Focus strictly on the electrical contacts. If the conductive metal contacts protrude (pins/blades), it is male. If the contacts are recessed holes, clamps, or sockets, it is female. Ignore the shape of the outer plastic casing, as this can be misleading, especially in automotive connectors.

A: They accommodate the standard sensor configuration required for operation: Power (Reference Voltage, usually 5V or 12V), Ground, and Signal Return. This setup allows the sensor to operate and send data back to the control unit efficiently while maintaining a compact form factor.

A: Header usually refers to board-mounted connectors soldered onto a PCB (often male, but female headers exist for stacking boards). Socket generally implies a wire-mounted or panel-mounted receptacle intended to receive a plug. However, these terms are sometimes used interchangeably depending on the industry.