Views: 0 Author: Site Editor Publish Time: 2026-01-22 Origin: Site

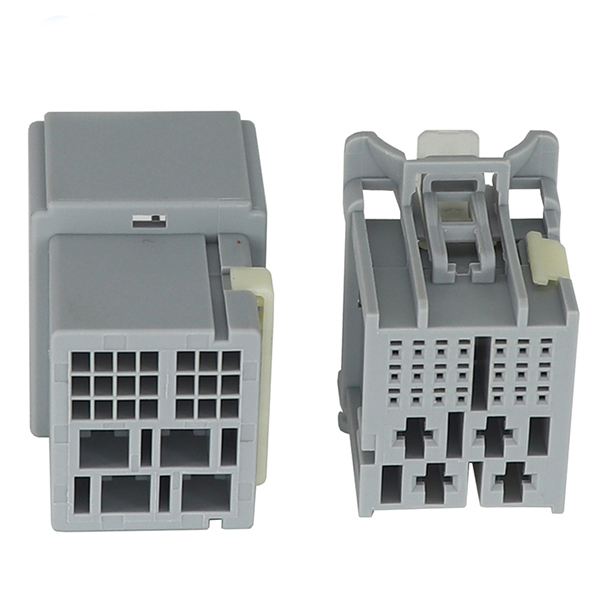

In the high-stakes world of industrial automation, unplanned downtime is the ultimate enemy. A single stopped production line can cost thousands of dollars per minute, eroding profit margins instantly. While engineers often scrutinize PLCs and high-end sensors, the humble interconnection components frequently become the overlooked single point of failure in critical systems. Specifically, the female connector is often underestimated as a mere passive socket.

In reality, the female receptacle is the active mechanical partner in any mating pair. It houses the critical spring mechanisms and contact beams responsible for maintaining the Normal Force required for electrical continuity. In harsh industrial environments—characterized by heavy vibration, thermal shock, and aggressive contaminants—investing in high-quality female connectors is not an optional expense. It is a strategic necessity for ensuring signal integrity, safety compliance, and long-term Total Cost of Ownership (TCO). This article explores why build quality in these components drives system reliability.

The Active Half: Female connectors contain the spring elements; their material quality determines the durability of the connection over thousands of mating cycles.

Hidden Risks of Low Quality: Substandard plating and weak contact physics lead to fretting corrosion, intermittent signal loss, and potential arcing in power applications.

TCO vs. BOM Cost: High-quality connectors reduce maintenance intervals and liability risks, offsetting their higher initial unit price.

Critical Evaluation Metrics: Decision-makers must look beyond rated current, focusing on derating curves, contact resistance stability, and housing flammability ratings (UL94).

When evaluating components, many buyers stop at the datasheet summary: rated voltage, current capacity, and pin count. However, the true reliability of a connector lies in the physics occurring at the microscopic level inside the receptacle. The female side of the connection performs the heavy lifting, mechanically gripping the male pin to ensure a stable electrical path.

The fundamental metric for connector reliability is Normal Force. This is the perpendicular pressure exerted by the female contact beam against the male pin. High-quality female connectors utilize high-performance alloys, such as Phosphor Bronze or Beryllium Copper, to maintain this pressure consistently over time.

Budget alternatives often use brass or lower-grade alloys that suffer from stress relaxation. Over time, especially under thermal cycling, these materials lose their elasticity. The spring mechanism relaxes, causing the normal force to drop. Once this pressure falls below a critical threshold, the connection becomes susceptible to intermittent opens, particularly when the machine vibrates.

The manufacturing process of the contact itself dictates its mechanical robustness. There are two primary methods: Stamped and Formed contacts, and Precision Machined (Turned) contacts. While stamped contacts are cost-effective for consumer electronics, industrial applications often demand the structural integrity of machined contacts.

| Feature | Stamped and Formed Contacts | Precision Machined (Turned) Contacts |

|---|---|---|

| Manufacturing Process | Sheet metal cut and folded into shape. | Solid metal rod cut and drilled on a lathe. |

| Structural Integrity | Hollow or folded; susceptible to crushing. | Solid construction; high resistance to mechanical shock. |

| Contact Density | Limited by sheet thickness and bending radii. | Allows for very high density and fine pitch. |

| Primary Use Case | High-volume, low-stress applications (Consumer). | Critical reliability, high-vibration (Industrial/Mil-Spec). |

Machined female contacts offer superior density and durability. Because they are carved from solid material, they do not suffer from the weak points associated with folded sheet metal seams. This makes them the industrial standard for critical reliability where failure is not an option.

The plating on the contact surface serves as the primary defense against oxidation. The choice between Gold and Tin plating is not arbitrary; it depends heavily on the application physics. Gold is essential for low-voltage signal integrity because it does not oxidize, ensuring data transmission remains error-free even at low currents. Tin, conversely, is often used for stable high-power connections where higher normal forces can break through the tin oxide layer (fretting).

A hidden risk in low-quality connectors is plating porosity. If the manufacturing process is rushed or cheapened, the gold or tin layer may have microscopic holes. These pores allow oxygen to reach the base metal (substrate), causing it to rust from the inside out. Quality manufacturing ensures non-porous plating, effectively sealing the base metal and guaranteeing longevity.

Industrial environments are hostile. Machinery generates heat, motors create vibration, and wash-down cycles introduce moisture. A female connector must act as a fortress, protecting the electrical contact from these external aggressors.

One of the most common causes of failure in factory automation is fretting corrosion. This phenomenon occurs when machinery vibration causes micro-movements between the mated pin and socket. These microscopic shifts scour the plating surface, eventually wearing it down to the base metal. Once the base metal oxidizes, resistance spikes, and the signal fails.

To combat this, high-quality female connectors employ multi-point contact designs. Technologies like dual-beam or crown springs ensure that the pin is gripped from multiple sides. If vibration momentarily breaks contact at one point, the others maintain continuity. Furthermore, floating housing structures allow the contact to move slightly within the insulator, absorbing vibration energy rather than transferring it directly to the mating interface.

A rating of IP67 or IP68 on a spec sheet is meaningless if the seal fails after a month of operation. The longevity of the Ingress Protection relies heavily on the materials used for O-rings and gaskets. Budget connectors may use cheap rubber that becomes brittle and cracks when exposed to temperature fluctuations or industrial chemicals.

Premium connectors utilize UV-resistant silicone or Viton O-rings. These materials resist degradation and maintain their elasticity even after repeated thermal cycling. Additionally, the locking mechanism plays a vital role. Whether it is a threaded M12, a bayonet, or a push-pull system, the lock maintains the necessary compression on the seal. It also prevents accidental decoupling, which is a frequent safety hazard in busy production environments.

Engineers must understand that Rated Current is often a theoretical maximum measured at room temperature (typically 20°C). However, industrial cabinets rarely operate at room temperature. As ambient heat rises, the connector's ability to carry current diminishes.

Quality manufacturers provide Derating Curves. These graphs visualize the safe operating current across a range of temperatures. For example, a connector rated for 10A might only be safe for 5A when the environment reaches 85°C. Relying on budget options that do not provide this data is a gamble; they may melt or fail catastrophically under loads that seem safe on paper.

As Industry 4.0 drives the adoption of the Industrial Internet of Things (IIoT), the demand for data speed and power density has skyrocketed. The female connector is now a critical node in high-speed data networks and high-power distribution systems.

For data-heavy applications, such as vision systems or real-time monitoring, impedance matching is critical. If the connector introduces an impedance mismatch, it causes signal reflection (insertion loss), resulting in data errors or reduced bandwidth. High-quality connectors are engineered to match the impedance of the cable, ensuring a seamless path for high-frequency signals.

Shielding is equally important. Factory floors are noisy environments filled with electromagnetic interference (EMI) from Variable Frequency Drives (VFDs) and large motors. Quality female connectors feature 360-degree EMI shielding, often using metal shells or conductive gaskets, to protect sensitive data streams from corruption.

When dealing with power, safety is paramount. Female connectors are typically designed as the live side of the connection to prevent accidental shock. Touch-safe designs, rated as IP2X, ensure that a standard test finger cannot touch the live contacts inside the housing. This is a critical compliance requirement for user safety.

Furthermore, some systems require Hot-Plugging—mating or unmating the connector while it is under electrical load. This action creates an electric arc that can damage the contact surfaces. High-end connectors incorporate sacrificial contact tips. These tips take the brunt of the initial arc damage, preserving the main conductive path for the steady-state connection.

The true test of quality is not the initial contact resistance, but how stable that resistance remains over time. A factory-fresh connector might show low resistance, but after 500 hours of salt spray exposure or 1,000 mating cycles, a low-quality unit will see resistance spikes. These spikes cause voltage drops, which can lead to sensor errors or motor inefficiencies. Reliable connectors maintain a flat resistance curve throughout their lifecycle.

Procurement departments often focus on the Bill of Materials (BOM) cost, pushing for the lowest price per unit. However, this Price per Pin mentality ignores the substantial operational costs associated with failure.

Some designers opt for hardwiring components directly to boards or terminals to save money. While the initial material cost is lower, the hidden costs are high. Hardwiring is labor-intensive, difficult to repair, and prone to inconsistent quality, such as cold solder joints that fail under vibration. Modular connectorization standardizes the connection quality and shifts the reliability burden from the manual laborer to the precision-manufactured component.

Quality female connectors facilitate a modular machine design. If a sensor fails on a production line, a modular connection allows for a Plug and Play replacement. A technician can swap the faulty unit in seconds without needing to rewire the entire cabinet. This speed directly translates to reduced downtime.

Additionally, supply chain assurance is a major factor in TCO. Buying from reputable OEMs guarantees traceability and compliance with global environmental standards like RoHS and REACH. Unverified grey-market alternatives often lack this documentation, exposing the company to legal liabilities and compliance violations.

When calculating TCO, consider the cost of failure. If a production line stops for one hour, the lost revenue often dwarfs the price difference between a standard and a premium connector. Investing in high-quality interconnects acts as an insurance policy against these expensive stoppages.

Selecting the right female connector requires a structured approach. Engineers should follow a strategic framework to ensure the chosen component matches the application's rigor.

Begin by creating an environmental matrix. Document the expected vibration levels (measured in Gs), the operating temperature range, exposure to chemicals or oils, and the expected mating frequency. This profile acts as the baseline for all subsequent decisions.

Do not rely solely on the catalog summary. Request detailed technical data regarding mating force, unmating force, and contact wiping length. A longer wiping length ensures that the contact cleans itself of oxides during mating, which is crucial for reliability in dirty environments.

The plastic housing is more than just a holder; it provides structural support and insulation. Different plastics suit different needs:

PA66 (Nylon): Standard for general-purpose applications.

PBT (Polybutylene Terephthalate): Preferred for wet environments due to its superior resistance to hydrolysis (water absorption).

Additionally, ensure the housing meets UL94 V-0 flammability standards, especially for safety-critical areas where fire resistance is mandatory.

Finally, look for evidence of specific validation tests. A reputable supplier will provide reports on Thermal Shock (EIA-364-32), Vibration (EIA-364-28), and Mixed Flowing Gas (MFG) testing. These reports prove that the connector can withstand the specific corrosive and physical stresses of the intended environment.

The female connector acts as the guardian of system reliability. It serves as the physical and electrical bridge between critical components, and a failure here negates the quality of every other device in the chain. Whether managing gigabits of data or kilowatts of power, the integrity of this connection defines the uptime of the entire system.

Buyers and engineers must shift their focus from minimizing Price per Pin to minimizing the Cost per Year of Reliable Operation. By prioritizing high-performance alloys, robust plating, and validated environmental resistance, companies can drastically reduce the risk of unplanned downtime.

We advise engineering teams to engage with suppliers early in the design phase. Reviewing derating curves and material specifications before locking in a Bill of Materials prevents costly redesigns and ensures that the chosen connector is truly fit for the industrial floor.

A: The distinction lies in the mechanical design. The male connector features protruding pins or prongs. The female connector has recessed sockets equipped with spring contacts that accept and grip the male pins. In power applications, the female side is typically the live side to prevent accidental contact with energized parts, enhancing safety.

A: Plating protects the base metal from oxidation and defines durability. Gold plating is ideal for low-voltage data applications because it does not corrode, ensuring signal integrity. Tin plating is cost-effective for high-current power connections, where high normal force breaks through oxides, though it generally offers a lower cycle life than gold.

A: A derating curve shows how much current a connector can safely handle as the ambient temperature rises. A connector rated for 10A at 20°C might only support 5A at 85°C. Engineers use this curve to size the connector appropriately for the maximum expected operating temperature of the equipment.

A: The primary cause is fretting corrosion. Vibration causes microscopic movements between the mated surfaces, wearing away the protective plating. This exposes the base metal to oxidation, creating a resistive layer that blocks electrical flow, leading to intermittent signal loss or complete failure.

A: Machined (turned) contacts are generally better for rugged industrial use. They are carved from solid metal, offering superior structural integrity, higher power density, and better resistance to vibration and mechanical shock compared to stamped contacts, which are folded from sheet metal. Machined contacts justify their higher cost through increased reliability.

content is empty!