Views: 0 Author: Site Editor Publish Time: 2026-01-20 Origin: Site

In the architecture of electronic systems, the concept of gender is far more than a simple mechanical designation. The female connector, often referred to as a socket or receptacle, serves as the foundational interface for safety, power distribution, and signal integrity. It is not merely a hole designed to accept a pin; it is a complex assembly engineered to shroud live circuits and ensure consistent contact pressure. Misunderstanding its function can lead to catastrophic failures, ranging from intermittent signal loss in data centers to dangerous electrical shocks in industrial environments.

Industry standards strictly dictate the placement of these components based on the Source Rule. To protect users from accidental contact with live conductors, the female connector typically resides on the power source side. This touch-safe design philosophy prevents short circuits and arc flashes during mating and unmating cycles. While simple male-to-female mating seems intuitive, the engineering behind the female interface involves intricate contact physics, spring forces, and housing materials.

This article moves beyond basic definitions to categorize these components into three distinct functional classes: Panel-Mount Interfaces, Cable-End Extensions, and Internal Wire Terminals. By understanding these categories, engineers and procurement leads can better navigate the complex market of connectivity. You will learn how to select the correct interface based on mounting integrity, environmental sealing, and cycle life, ensuring your system complies with safety regulations and performs reliably in the field.

Safety First: Female connectors are the primary mechanism for electrical safety compliance (IEC/NEMA), designed to house live circuits and prevent contact with conductors.

The Three Functional Classifications: 1. Panel-Mount Receptacles: The fixed interface on a device chassis (e.g., USB ports, wall outlets). 2. Cable-Mount Sockets: Mobile connectors attached to cables for extension or power coupling (e.g., IEC C13 cords). 3. Wire Terminals/Housings: Internal crimp or insulation displacement components (e.g., headers, spade connectors).

Decision Drivers: Selection depends on mating cycles, retention force requirements, and environmental sealing (IP ratings), not just physical fit.

At its core, a female connector is a precision-engineered device containing internal sockets, contacts, or receptacles. Its primary mechanical function is to receive and grip the conductive pins or blades of a male counterpart. This gripping action relies on internal spring mechanisms, often made from phosphor bronze or beryllium copper, which maintain constant pressure against the male pin to ensure low contact resistance.

Regulatory bodies such as UL, CSA, and the IEC enforce strict guidelines regarding connector gender for power applications. The fundamental rule is the Touch-Safe principle. Since the female interface houses its conductive elements deep within an insulating body, it is inherently safer for live power sources. For example, a standard wall outlet is female because it carries lethal voltage. If it were male, exposed prongs would present an immediate electrocution hazard.

This design mitigates risks associated with arc flash and accidental human contact. In high-voltage DC applications, the depth of the female housing also helps extinguish arcs that may occur during disconnection, protecting both the operator and the equipment.

Confusion often arises when distinguishing between gender and mobility. It is crucial to separate the two concepts:

Gender (Pin vs. Socket): Determined solely by the conductive element. If it has holes or sockets, it is female. If it has pins, it is male.

Mobility (Plug vs. Jack): Determined by whether the component is fixed or mobile. A Plug usually moves, while a Jack or Receptacle is stationary.

A connector can be both female and mobile. A classic example is the socket end of an extension cord. It is mobile (attached to a cable) yet female (designed to receive a plug). Understanding this distinction is vital when reading schematics or ordering parts to avoid gender mismatch errors.

Panel-mount receptacles serve as the Target connectors in an electronic system. They are fixed permanently to a device housing, control panel, or Printed Circuit Board (PCB). These interfaces act as the gateway for data and power to enter or exit a device. Because they are often user-facing, they must withstand significant mechanical abuse and environmental exposure.

You encounter these interfaces daily. In IT infrastructure, the female RJ45 ports on routers and switches allow for network connectivity. On personal computers, USB Type-A and Type-C ports are female panel-mount receptacles designed for thousands of interactions. In power distribution, the wall outlet is the most ubiquitous example. For industrial radio equipment, female BNC or SMA bulkhead connectors provide the antenna interface.

When selecting a panel-mount component, engineers must evaluate three critical factors:

Mounting Integrity: How is the component attached to the board? Through-hole technology generally offers higher mechanical strength compared to Surface Mount Technology (SMT). For ports that users plug and unplug frequently, through-hole anchors prevent the receptacle from ripping off the PCB.

Mating Cycles: Not all receptacles are equal. A USB port on a laptop requires a rating of 10,000+ mating cycles. Conversely, a maintenance port inside a server might only need a rating of 50 cycles. Specifying a high-cycle connector for a one-time use application wastes budget, while the reverse leads to field failure.

Shielding: High-speed data interfaces require metal shielding shells. These cages connect to the chassis ground, protecting the signal from Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI).

The second category consists of mobile connectors attached to the end of a wire or cable. These are often called sockets or couplers. Their primary function is to couple with a male plug to extend a cable run or to terminate a patch cord securely.

In power transmission, the female IEC C13 connector is industry standard. It attaches to the cable end and plugs into the male inlet of a computer power supply. In the professional audio world, the female end of an XLR microphone cable connects directly to the microphone. Industrial automation relies heavily on M12 field-wireable sensor connectors, where the female socket on the cable brings power and data to field devices.

Unlike fixed panel connectors, cable-mount types face dynamic stresses. Movement, twisting, and pulling are constant threats.

| Feature | Importance | Example |

|---|---|---|

| Strain Relief | Prevents the cable from fraying or detaching at the termination point. | Rubber boot on an Ethernet cable or cable gland on a heavy-duty power cord. |

| Locking Mechanisms | Ensures the connection holds during vibration or accidental tugs. | Screw-locking M12 connectors vs. friction-fit AC mains plugs. |

| Field Serviceability | Determines if the connector can be repaired or must be replaced. | Screw-terminal types allow field repairs; molded plugs do not. |

For critical infrastructure, the choice between a molded connector (cheap, durable, non-repairable) and a field-wireable version (expensive, repairable) often dictates the maintenance strategy.

Often overlooked, internal wire terminals are the invisible heroes of electronic reliability. These female connectors reside inside the equipment, facilitating board-to-wire or wire-to-wire connectivity. They are not meant for end-users but are critical for assembly and repair.

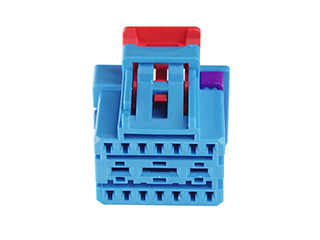

In the automotive and HVAC sectors, female disconnects (commonly called spade connectors) are ubiquitous. They crimp onto wires and slide onto male tabs. Inside computers, 2.54mm pitch DuPont style sockets connect LEDs, power buttons, and fans to the motherboard. Insulation Displacement Connectors (IDC) are another variant, biting through ribbon cable insulation to create contact without stripping wires, commonly found in legacy drive cables.

Reliability here focuses on electrical stability over time rather than plugging frequency.

Contact Resistance: Manufacturers aim for a gas-tight connection. This means the pressure between the wire and the terminal is high enough to prevent oxygen from entering and causing oxidation, which would increase resistance and voltage drop.

Retention Force: Internal components vibrate. A female housing must grip the male header pins securely enough that they do not walk out during transport or operation. Locking ramps are often added to the plastic housing for this reason.

Tooling Requirements: Many internal terminals require proprietary crimping tools. Using generic pliers instead of the specific ratchet crimper leads to weak connections and is a leading cause of premature failure.

Choosing the right female connector requires balancing multiple performance metrics. Procurement and engineering teams should use a decision matrix to filter options.

Durability requirements vary wildly. Internal maintenance headers, which might only be disconnected during a rare repair, fall into the Low Cycle category (under 50 cycles). High-endurance consumer ports, like the charging port on a phone, fall into the High Cycle category and use harder contact plating (like gold) to resist wear.

Standard office equipment uses unsealed connectors. However, outdoor industrial applications demand IP67 or IP68 ratings. These ratings certify that the female housing can prevent water and dust ingress. For instance, an N-Type female connector on a telecom tower must remain waterproof even during storms. Failing to specify the correct IP rating inevitably leads to corrosion and system failure.

Using standard geometries (NEMA, IEC, USB) reduces supply chain risk. If a proprietary female connector is selected, you lock the product into a single vendor. While proprietary designs can offer unique features, the ROI impact of supply chain resilience usually favors standardized components.

Engineers must examine derating curves. A connector rated for 10 Amps at 20°C might only safely handle 5 Amps at 80°C. Furthermore, the physical spacing inside the female housing determines the voltage clearance. High-voltage applications require larger housings to prevent arcing between contacts.

Even with the correct component, implementation errors can introduce severe risks.

One of the most dangerous DIY errors is the creation of a suicide cable—a cord with male plugs on both ends. This configuration bypasses the safety rule that requires the source to be a female connector. If such a cable is plugged into a live wall outlet, the exposed pins on the other end carry lethal voltage. Engineers must design systems that never require such a configuration.

Logistics often become complicated when legacy equipment meets new infrastructure. While gender changers (adapters) exist, stacking them degrades signal quality. In RF and high-speed data applications, every adapter introduces insertion loss and impedance mismatch. It is always preferable to terminate cables with the correct gender rather than relying on adapters.

A common failure mode in older equipment is contact splay. Over time, or due to the insertion of an oversized probe, the internal spring leaves of the female socket widen. This reduces contact pressure, leading to intermittent connections. Regular inspection of critical interfaces should include checking for loose retention force.

The term female connector encompasses a vast array of components, from the rugged wall outlets powering our homes to the microscopic sockets inside our smartphones. It serves as a broad category that includes fixed panel interfaces, mobile cable sockets, and internal wire terminals. While their forms differ, their function remains consistent: to provide a safe, reliable interface for power and data.

The choice of connector ultimately dictates the longevity and serviceability of the entire system. A poor choice in housing material or contact plating can turn a robust electronic design into a maintenance nightmare. Engineers must look beyond the spec sheet and consider the real-world environment where the device will live.

As a next step, we recommend auditing your current Bills of Materials (BOM). Verify that your selected connectors match the IP ratings and mating cycle specifications required by your users. Ensuring alignment here is the most effective way to prevent costly field failures.

A: They are designed this way for safety, adhering to the Touch-Safe principle. Female connectors house their conductive contacts inside an insulating structure (plastic or rubber), making it difficult for fingers or foreign objects to accidentally touch live parts. Male connectors have exposed pins, which would be dangerous if they were live and exposed. Therefore, industry standards like IEC and NEMA mandate that the energy source is always the female socket (like a wall outlet) to prevent shock and arc flash hazards.

A: A hermaphroditic connector, also known as a genderless connector, eliminates the male/female distinction. Each connector face is identical and can mate with any other connector of the same type. Examples include IBM Data Connectors and Anderson Powerpoles. These are highly efficient for inventory management because you do not need to stock separate male and female parts. They also allow for daisy-chaining cables indefinitely without needing gender-changing adapters.

A: In general electronics terminology, yes, a Jack usually refers to the fixed female receptacle (like an Audio Jack or RJ45 Jack). However, terminology can vary slightly by industry. In audio engineering, the distinction is strictly between Plug (mobile) and Jack (fixed). While the Jack is almost always female, the primary distinction is its stationary nature on a panel or chassis. It is safer to confirm the gender (socket vs. pin) rather than relying solely on the word Jack.

A: It depends on the construction type. Field-wireable connectors, often used in industrial settings (like screw-terminal IEC or M12 connectors), can be disassembled and repaired by re-stripping the wire and tightening the terminals. Molded connectors, common in consumer electronics (like standard USB cables or cheap power cords), cannot be repaired. If the internal contacts are damaged or the housing is cracked on a molded unit, the entire cable assembly must be replaced to ensure safety.

A: Schematic symbols vary by standard (ANSI vs. IEC), but female connectors generally feature visual cues representing a receiving shape. Look for a hollow semi-circle, a cup shape, or a bracket that encloses the male pin symbol. In simpler diagrams, it might be represented by an arrow pointing into a shape, or simply labeled with J (Jack) or F (Female). The symbol will typically look like it is designed to contain the opposing male symbol.